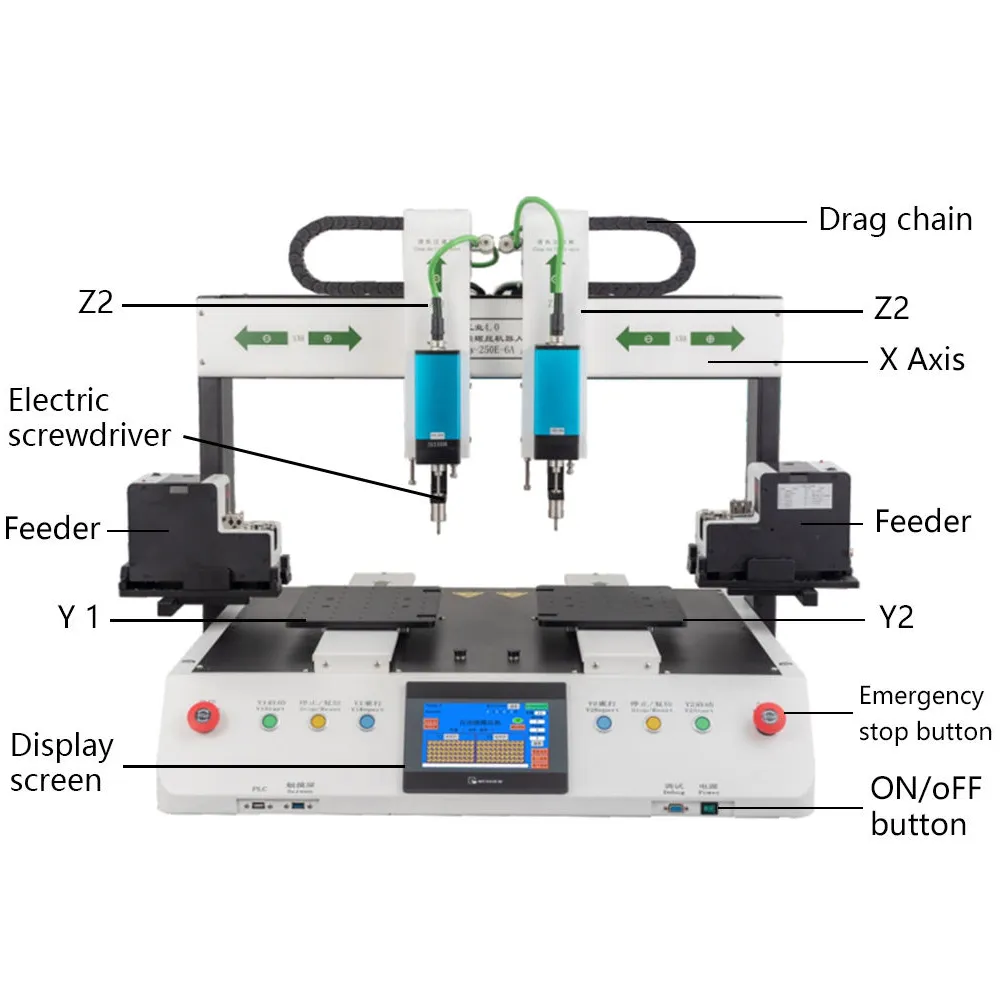

6 Axis Automatic Screw Tightening Machine

6 Axis Automatic Screw Tightening Machine XH-SC970S/SC550S

Dual Working Stations, Strong Compatibility, Can Work Alternately Left And Right, Double The Efficiency.

1. The screw picking method can support vacuum suction or magnetic suction;

2. It can drive stainless steel screws and meson screws (vacuum suction).

3. It supports deep holes, inclined holes, elastic surfaces, and surfaces with different heights (magnetic suction).

4. The screw tightening robot supports driving two different screws at the same time (one product), and the intelligent servo electric screwdriver supports three different torques at the same time.

5. The screw tightening machine can merge two processes to drive screws (after driving one process, stop, assemble the parts, and then drive another process screw).

6. Intelligent servo electric screwdriver, fast speed, high precision, low noise, long life, maintenance-free: torque (0.3-9KGf.cm), speed (0-3000 rpm), can be set arbitrarily on the touch screen.

7. The height of the feeder can be adjusted freely, supporting products of different heights, and strong compatibility.

8. Closed-loop stepper motor, high precision, position compensation, no step loss.

9. The automatic screw tightening machine equipped with self-developed motion control card, fool-style programming, optional drag-style adjustment, easy programming.

10. The auto screw tightening machine equipped with touch screen, dynamic display of lock status, electric screwdriver speed, electric screwdriver torque, real-time monitoring.

11. Four-axis double Y platform, can work alternately, high efficiency.

This screw tightening machine is suitable for Large and small household appliances, automotive electronics, instrumentation, toys, power supplies, mobile phones, LEDs,Tablet, computer keyboard, etc.

1. The screw picking method can support vacuum suction or magnetic suction;

2. It can drive stainless steel screws and meson screws (vacuum suction).

3. It supports deep holes, inclined holes, elastic surfaces, and surfaces with different heights (magnetic suction).

4. The screw tightening robot supports driving two different screws at the same time (one product), and the intelligent servo electric screwdriver supports three different torques at the same time.

5. The screw tightening machine can merge two processes to drive screws (after driving one process, stop, assemble the parts, and then drive another process screw).

6. Intelligent servo electric screwdriver, fast speed, high precision, low noise, long life, maintenance-free: torque (0.3-9KGf.cm), speed (0-3000 rpm), can be set arbitrarily on the touch screen.

7. The height of the feeder can be adjusted freely, supporting products of different heights, and strong compatibility.

8. Closed-loop stepper motor, high precision, position compensation, no step loss.

9. The automatic screw tightening machine equipped with self-developed motion control card, fool-style programming, optional drag-style adjustment, easy programming.

10. The auto screw tightening machine equipped with touch screen, dynamic display of lock status, electric screwdriver speed, electric screwdriver torque, real-time monitoring.

11. Four-axis double Y platform, can work alternately, high efficiency.

This screw tightening machine is suitable for Large and small household appliances, automotive electronics, instrumentation, toys, power supplies, mobile phones, LEDs,Tablet, computer keyboard, etc.

| Specification | XH-SC970S | XH-SC550S |

|---|---|---|

| Working area (X*Y*Z*R) | X1/X2:730*Y1/Y2:900*Z1/Z2:100mm | X1/X2:400*Y1/Y2:700*Z1/Z2:80mm |

| Moving speed (mm/s) | X/Y axis ≤ 500mm/s, Z axis ≤ 300mm/s | |

| Drive mode | Stepping motor + straight guide / servo motor + ball screw (alternative) | |

| Location accuracy | ±0.01~0.03mm | |

| Control system | Moving controlling and teach pendant | |

| Screw transmission method | Suction mode / blow mode (alternative) | |

| Electric screwdriver | 2 pc (alternative, can be increased upon request) | |

| Screw feeder | 2 sets | |

| Full-voltage | 220V | |

| Operating temperature | 5-40℃ | |

| Operating humidity | 20-90% no condensation | |

| Air pressure | 0-0.8MPa | |

| Dimension (W*D*H mm) | 1235*1080*780 | 1070*700*800 |

| Weight | around 220kg | around 150kg |

Get Your Custom Automation Solution Today

Fill out the form below to request a quote or consultation. Our team will help you find the perfect glue dispensing, potting, screw fastening, or soldering automation solution for your production needs.